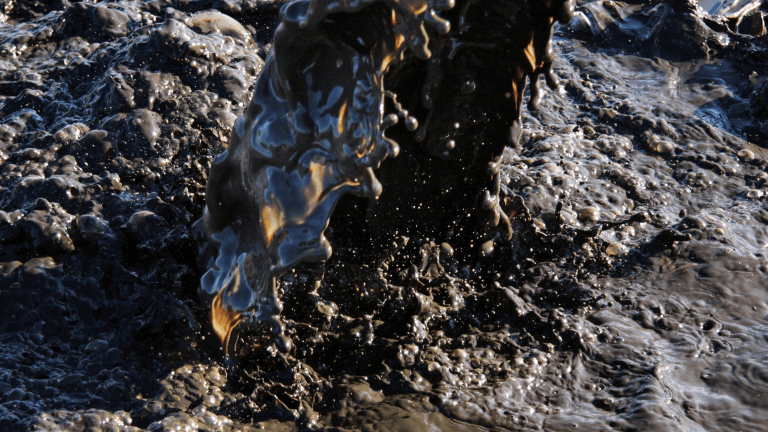

Hydrovac Waste

Hydrovac is a non-destructive excavation method that uses pressurized water and vacuum to safely expose buried utilities with minimal disruption.

Why Settle For Slurry?

Hydrovac (hydro excavation) is one of the cleanest ways to dig around buried utilities, but it creates a different kind of material problem: wet spoil. You’re left managing a slurry of water, sand, silt/clay, and jobsite debris that can’t be handled like dry excavated soils. Storage fills up fast, trucking gets expensive, and disposal rules can tighten depending on where the material came from.

Stuck on Sludge

Hydrovac waste is a mix of water and excavated ground material pulled into the tank during digging. In everyday civil work, that usually means sand and small aggregate blended with silt and clay fines. Those sticky fractions that keeps everything suspended. Depending on the jobsite, it can also include roots and organics, small asphalt fragments, base-course gravel, and general debris that gets picked up along the way.

In some locations, hydrovac spoil can be “questionable” even when it looks normal, especially near fueling areas, older industrial footprints, or redevelopment corridors where legacy impacts may be present.

Worth a Wash

Utilities & Municipal Maintenance

Daylighting gas, water, sewer, storm, and electrical lines creates steady volumes of slurry, especially in tight urban corridors where mechanical digging is risky.

Civil construction & traffic work

Potholing before directional drilling, sign and pole installs, guardrail work, and road rehab often produce a mix of wet granular, asphalt crumbs, and fines from subbase layers.

Winter work in cold regions

Frozen ground pushes more crews toward hydrovac. Slurry volumes increase, and the waste is harder to manage because it’s wetter, heavier, and often stored longer.

Telecom & fiber installs

Repeated small excavations add up fast. The material is often sandy but becomes “waste” because it’s saturated and mixed with fines.

Sustainability Starts with Saleable Slurry

With the right wet processing and dewatering setup, you can recover a coarse fraction (often sand) that may be suitable for reuse or resale where permitted, while concentrating fines into a smaller stream for targeted handling. Debris and organics can be removed upstream, and water can be cleaned and reused in a closed-loop approach depending on the system design.

The result is straightforward: less material exported as waste, more usable material recovered, and a cleaner, more predictable process.

Explore other real-world applications

See our case studies for proven results in the field.

Unsatisfied With Your Slurry?

Turn high-cost material into a controlled process. Whether you’re exploring feasibility or ready to design, we’ll walk through the details and the next steps. Let’s talk soil washing.